3D printing materials

Learn about the characteristics of individual materials and their areas

Applications in various industries.

Start / 3D printing materials

Produce durable, mechanically resistant parts

The material is the perfect combination of between the quality of the parts and the cost of their manufacture It is very well suited for the production of functional elements that are exposed to various types of chemicals. Its important advantage is also impacting resistance and thermoplasticsIt is most often used in orthopedics in the production of shoe insoles and sports articles, but it is also suitable for printing clasps and hinges.

Produce colorful and functional parts for a variety of industries

Designed material to produce functional parts in a full-color palette.

Ideally suited for the production of prototypes with fine details ensuring optimal dimensional accuracy PA 12 CB is most often used for the production of handles, instruments, presentation models, and labels. Our clients use the properties of full-color printing to place functional and unique QR codes and other markings on their projects.

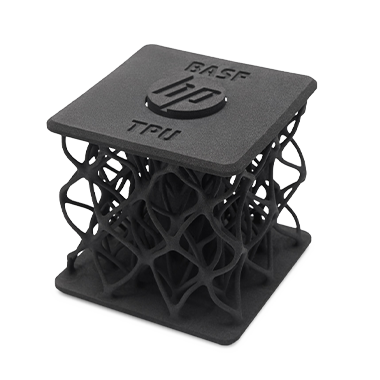

Produce flexible components with high precision

Universal material for use in the Multi Jet Fusion technology allows the production of parts with good flexibility and shock absorption while maintaining optimal accuracy and detail. BASF TPU also has good UV resistance and high thermal stability. Its great advantage is also the excellent quality of the printed surface. It is ideal for the production of shock-absorbing elements, pipes, car parts or footwear and orthopedic models.

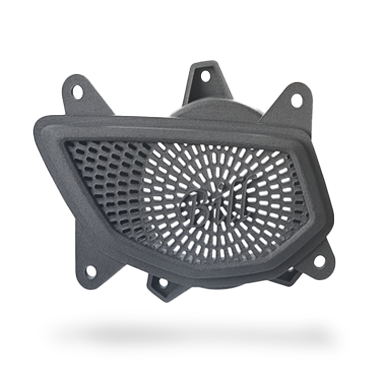

Produce precise and durable components

Polyamide is the most versatile and versatile choice for producing complex shapes. The PA 12 material is ideal for the production of prototypes and final elements. Used in the Multi Jet Fusion technology, it is characterized by good granularity, which is perfect for the production of high-density parts and low porosity. Material is ideal for the production of connectors, containers, or complex housings.

Produce thermoplastic components with high dimensional accuracy

A material with thermoplastic properties made of 40% glass spheres, which ensures optimal mechanical properties and high recallability. Perfect for the production of high rigidity components, instrumentation or all kinds of housings. Used in the Multi Jet Fusion technology, it is the optimal solution in terms of savings resulting from the recovery and re-use of unused powder.

Produce strong and moisture-resistant components with high efficiency in industrial production.

A material with the same properties as commonly used polypropylene plastics used in injection technology, the applications of which are almost unlimited. Thanks to its chemical resistance, low moisture absorption and long-lasting strength, polypropylene is ideal for the production of pipes, fluid conduction systems and containers. In addition to an unprecedented economy of use and efficiency, it allows you to reduce waste thanks to the possibility of reusing the remaining unused powder up to 100%.

Do You want to start cooperation with us?

Get Your instant quote or contact us directly