Start / 3D printing materials / BASF Ultrasint® TPU01 Material

BASF Ultrasint®

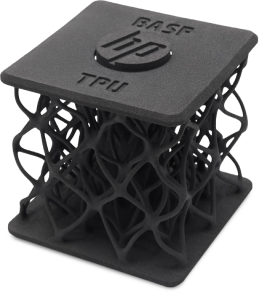

TPU01 Material

For the production of highly flexible components

The material is adapted to 3D printing in HP Multi Jet Fusion technology.

It is characterized by excellent flexibility while maintaining optimal parameters related to the detail of the model. Additional advantages of BASF’s TPU material are its thermal stability and resistance to UV radiation.

Most often it is used in the production of pipes, cables and shock-absorbing elements

Has the following certificates:

Appliance of the material

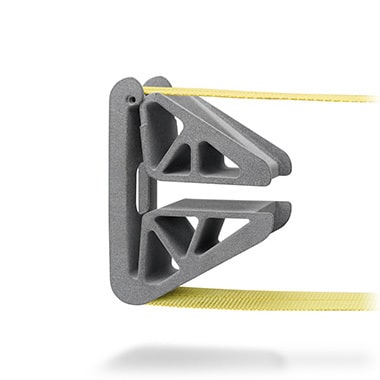

Production of elements responsible for cushioning, which must also demonstrate adequate breaking strength

Manufacture of pipes and conduits that must have sufficient flexibility during use.

- The use of the material in the automotive industry for the production of e.g. dashboard elements

- Printing of parts characterized by lattice structures, which allows you to save material for printing and obtain flexibility of the element while maintaining the necessary strength properties

- Production of orthopedic appliances (the material, thanks to its flexibility and durability, can increase the comfort of the life of people struggling with injuries such as joint sprains or bone fractures)

- The use of the material in the footwear industry for the production of shoe insoles, soles, and all shoes

- Printing of designer accessories with practical use (e.g. mobile phone cases)

Full technical specification of the material

Detailed information on BASF Ultrasint® TPU 01

Other materials for 3D printing

Find out about their properties and areas of application

Do You want to start cooperation with us?

Get Your instant quote or contact us directly