Post-processing

Finishing treatment of external surfaces for 3D printed parts

Start / Production line / Post-processing

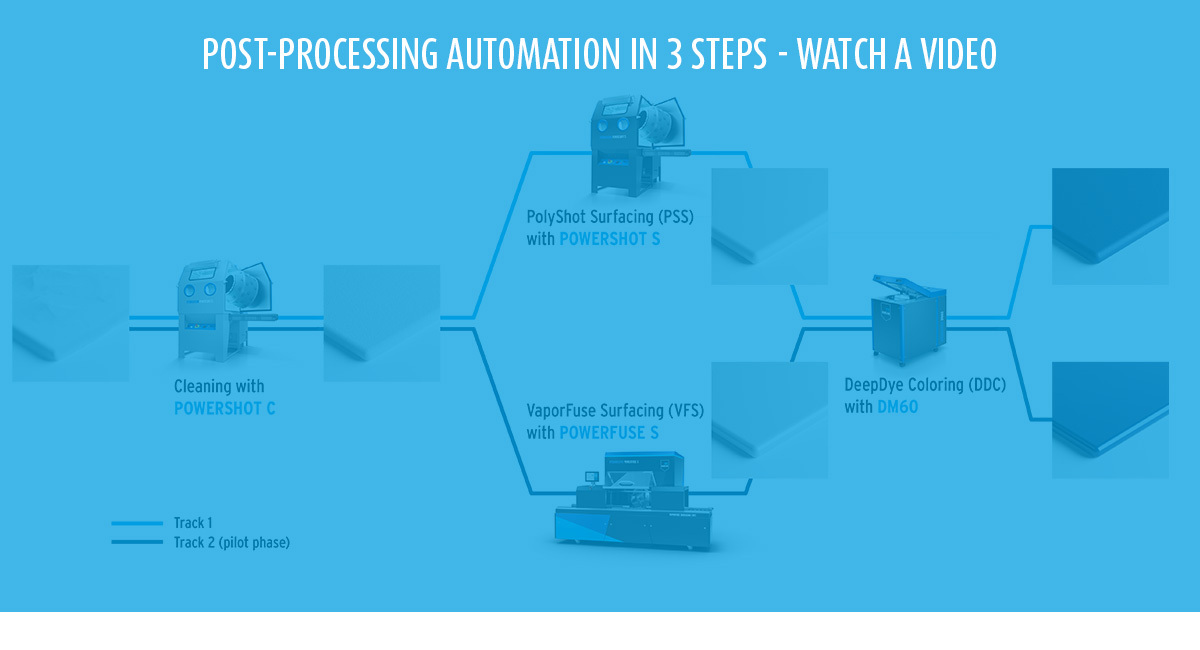

Process workflow

using innovative machines of DyeMansion company

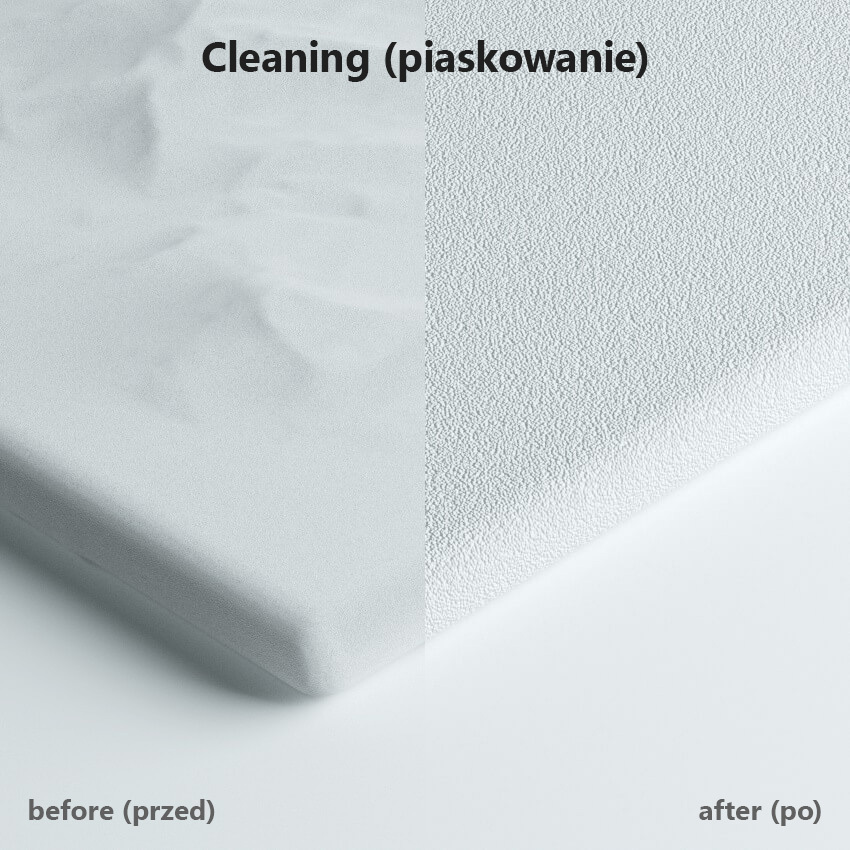

Finishing processing of 3D printed parts is an integral part of the additive manufacturing process. Most often, it consists in cleaning the parts from unnecessary fragments adjacent to the structure of the printed model. In the case of the HP Multi Jet Fusion technology, which we have at our disposal, the basic procedure in post-processing is cleaning the parts from unfused powder, which is the building material of the printed parts. This process is carried out using a sandblaster adapted for this purpose. A wide range of DyeMansion devices also allows You to smooth the outer surfaces of printed elements with the PowerShot S machine and to color the printed parts in the full range of RAL colors palette.

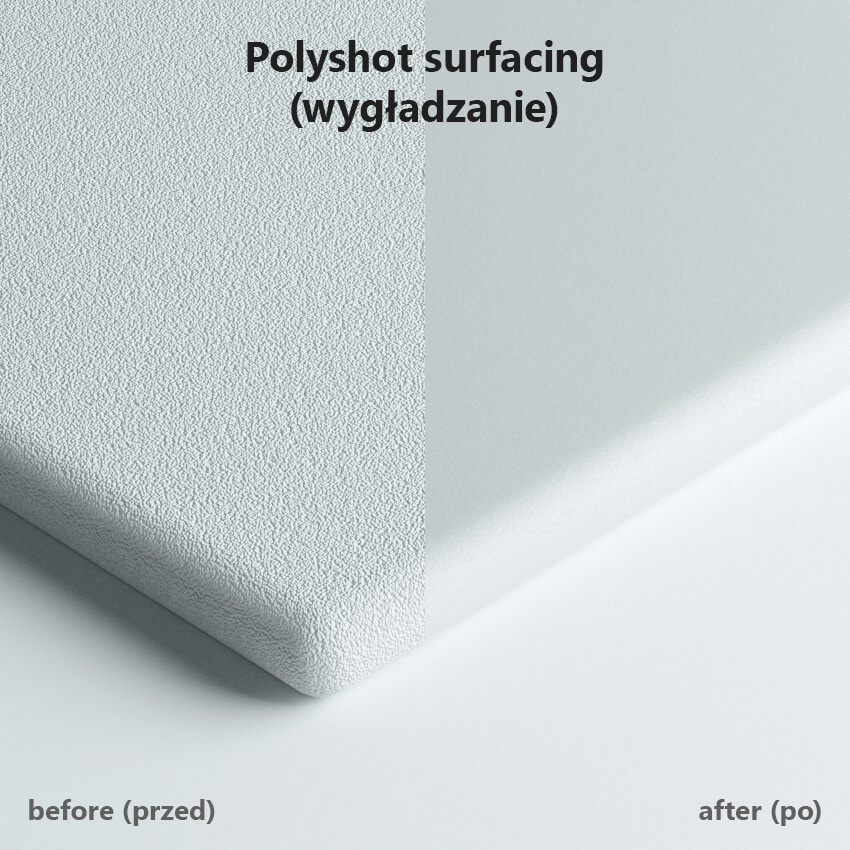

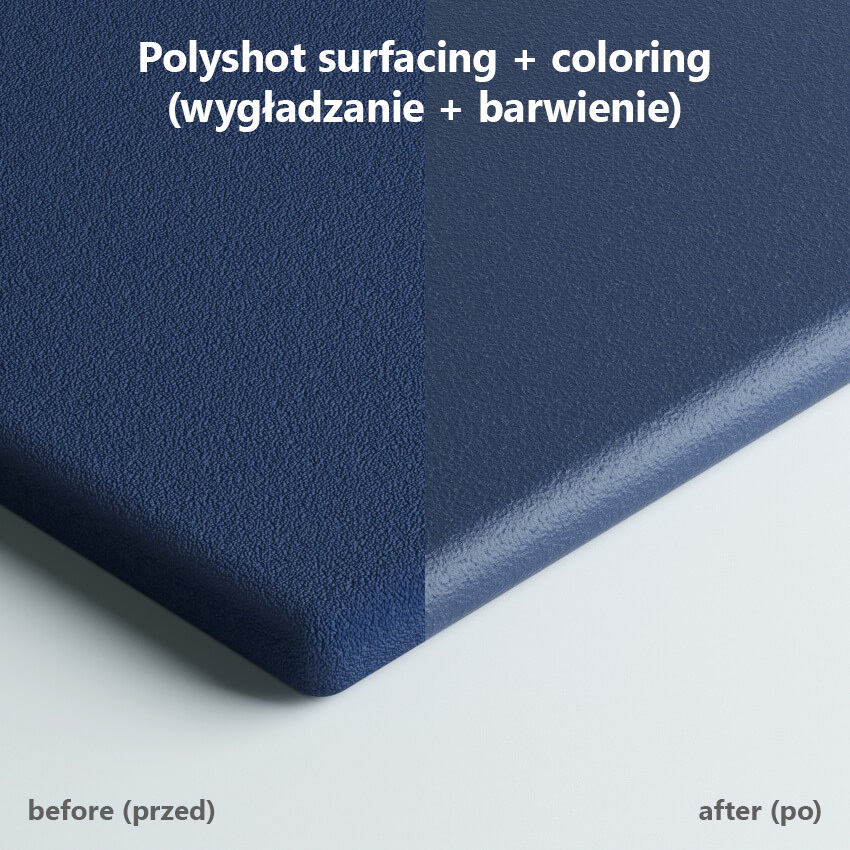

Post-processing effects

of sandblasting, surface smoothing and coloring

The processes that the printed parts are subjected to, can significantly improve the quality of the external structures of the printed elements. Smoothing parts with a PowerShot S machine makes them comparable to injection molded parts. The possibility of tinting the printed parts with any color included in the RAL palette makes the level of finish high enough to meet even the highest quality requirements.

Most importantly, finishing processes while using DyeMansion machines do not adversely affect the strength parameters and dimensional accuracy of the finished parts.

Post-processing on request

for those who require the highest quality of workmanship

For customers who expect the highest quality finishing of parts, we offer our post-processing services. When using DyeMansion machines, we will do our best to ensure that the finished products meet the appropriate quality requirements.

To commission us to perform post-processing service , select the appropriate options when evaluating the file online. The following processes are possible: sandblasting, smoothing the surface of the model and dyeing to a selected color from the RAL palette.

If you are interested in post-processing on a ready-made, previously printed model, please contact us using the form available here.

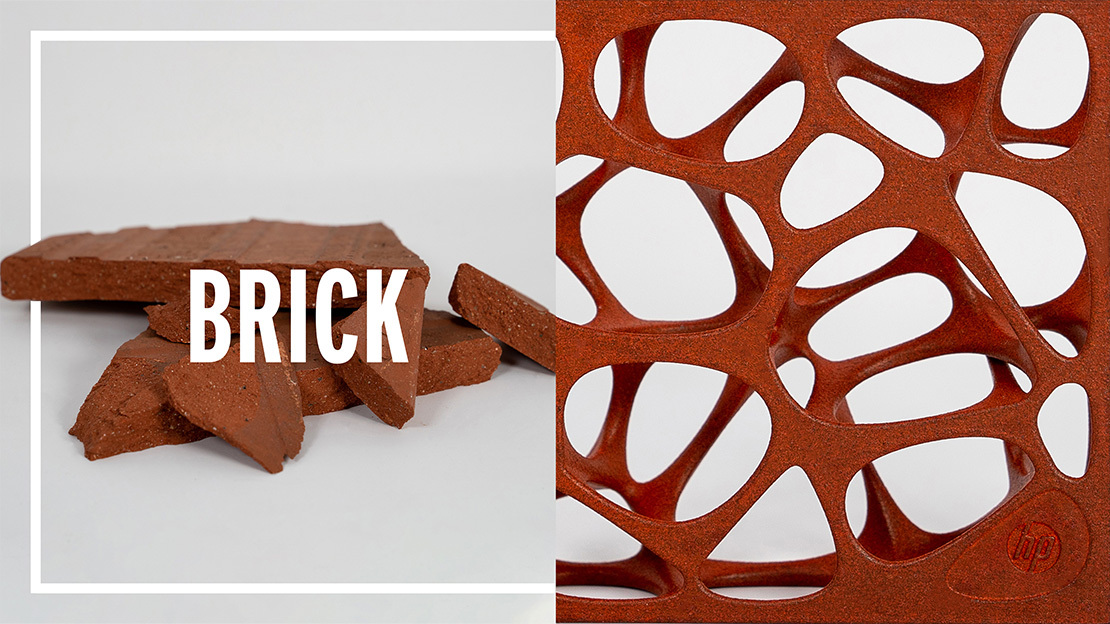

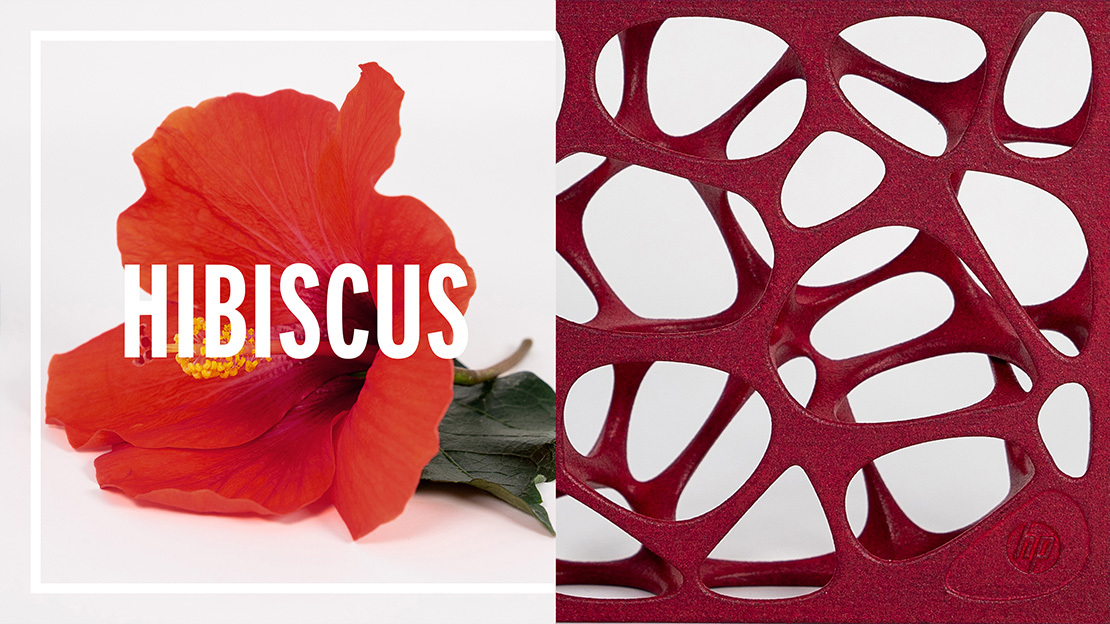

DyeMansion vibrant colors for grey raw material

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis

17 vibrant colors developed especially for grey HP Multi Jet Fusion parts, opening up completely new fields of applications for additive manufactured products produced with the HP Multi Jet Fusion process. A previously unseen color spectrum on grey parts enables vibrant shades when dyeing HP 3D HR PA 12.

17 standard colors

17 standard colors

Developed on HP 3D HR PA 12 with PSS finish, other materials may vary

Developed on HP 3D HR PA 12 with PSS finish, other materials may vary

The only vibrant color range for grey MJF parts on the market

The only vibrant color range for grey MJF parts on the market

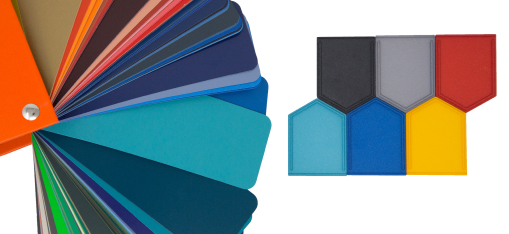

Dyemansion standard colors for white materials

As shown on the basic color fan, all 17 DyeMansion standard colors are developed on EOS PA2200 with our PolyShot Surfacing (PSS) finish. The final color appearance may vary with other materials. These colors are frequently used in our On-Demand finishing service and our proven basics.

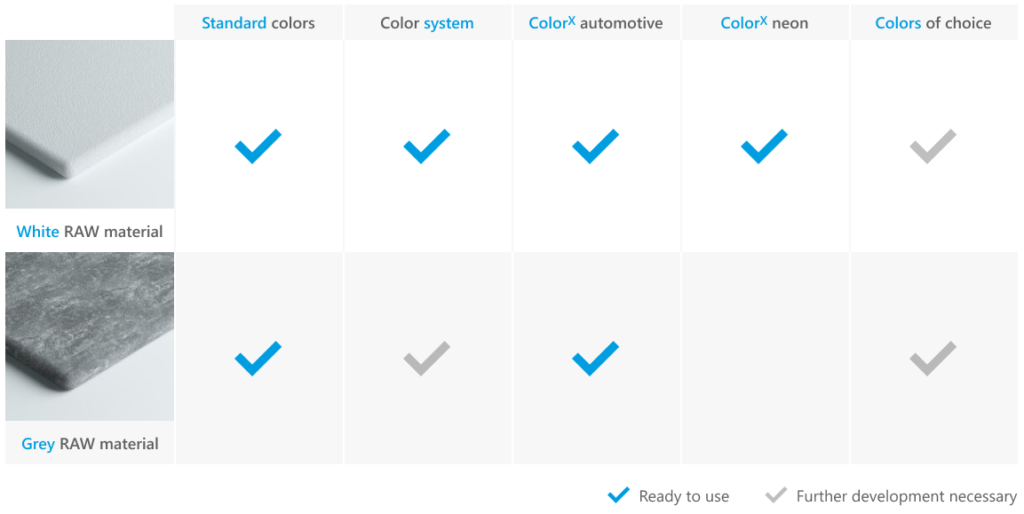

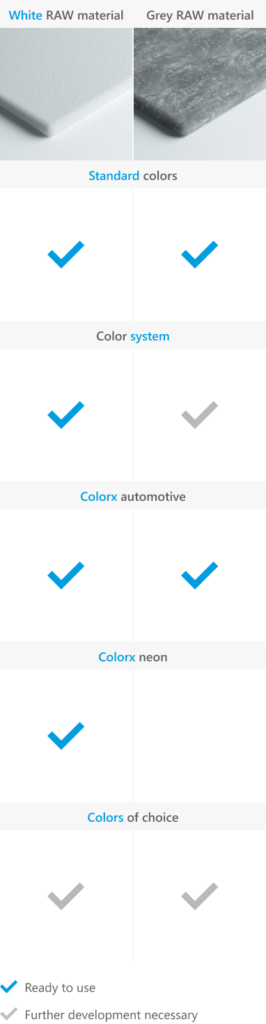

RAL color system

Benefit from the entire RAL color range: A large choice of colors with no waiting times and no additional development costs. Since the coloring and the appearance depend very much on parameters such as material and finish, the RAL palette was developed with defined parameters, namely for EOS PA2200 and PolyShot Surfacing (PSS) finish.

Pantone color system

For all the designers and fashion lovers, we can create any Pantone TPG color for every surface finish. It is possible to adapt to any color system on request.

ColorsX automotive

Developed to meet the automotive requirements for light and heat resistant car interior parts.

ColorsX Neon

Vibrant colors designed for outstanding sportswear and lifestyle applications.

Colors of choice

Design 3D-printed parts in your corporate color or any color of choice you like! Together with our customers we are even able to develop for example special color shades that are matching their skin tones. Replicating the exact color of an injection molded part is key for manufacturing projects. This is why we develop every individual color directly on your raw material.

Color option & RAW material

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis

More information on the partner's website

Other elements of the AM3D production line

Explore the all stages of the additive manufacturing process

Do You want to start cooperation with us?

Get Your instant quote or contact us directly