Material testing

Possibility to use and advanced equipment to accurately determine material properties.

Start / Material testing

Precision Shimadzu AGX-V testing machine

Thanks to the use of top-shelf testing machines, we can test the physical parameters of a given model for our customers. We carry out research orders in the field of checking the strength of the material under compression and also tensile strength and measuring the shear resistance.

It is also possible to make a test of bending resistance and determine the elastic modulus of the tested elements. Our testing machines meet the ISO, JIS as well as ASTM standards.

Aging Test Chamber

Within a few days or weeks, it can recreate the damage to the material that occurs in weather conditions over the course of months or years. To simulate weathering, the materials in the chamber are exposed to alternating cycles of UV radiation and moisture at a controlled elevated temperature. The sunlight is simulated using special UV fluorescent lamps. To simulate dew and rain, condensation or water spray is used.

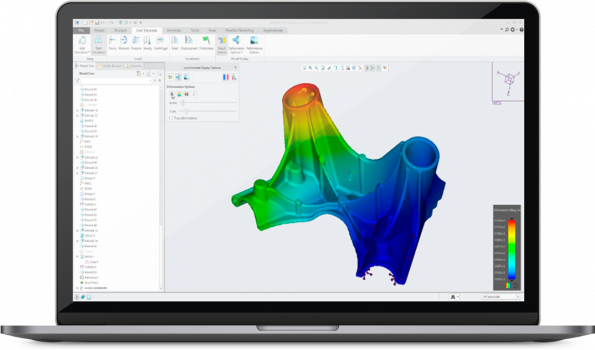

Finite element method

The Finite Element Method is an advanced method for solving systems of differential equations. Thanks to it, we have the opportunity to test the strength of the structure, simulate deformations, stresses, displacements, heat and fluid flow. You can also study the dynamics, kinematics and statics of machines, as well as electrostatic, magnetostatic and electromagnetic activities.

MarSurf PS 10 device

We dispose of an advanced device that allows you to test the surface roughness and prepare ready-made results directly on the measuring instrument. Thanks to it, we can precisely check the smoothness of the surface and the quality of the post-processing performed earlier, which is particularly important for products whose finish quality is the most important factor during production.

Do You want to start cooperation with us?

Get Your instant quote or contact us directly

Device for measuring abrasion resistance

The wear resistance of a component during operation and mechanical loads is a key issue when choosing the right material. Our measuring equipment allows you to test a sample with a thickness of up to 6.35 mm in terms of surface resistance to various types of abrasion. Our research may facilitate the selection of the appropriate material for the project.

Precision scale PS R2.M

The use of high-capacity precise scales with a single-point method of fixing the pan guarantees very good geometry, which allows to avoid measurement errors. The accuracy of the scale is 0.01g with a load capacity of up to 10 kg. In the prototype stage of the product, the precision of our tests may therefore contribute to the selection of the most optimal material for 3D printing.

Positector 200 advanced with measuring probe and Shore A and D hardness measuring attachments

In order to determine the thickness of the coating of a given element, we select the most optimal measurement method, carefully selected for the material our element is made of. At our disposal we have the magnetic method, the eddy current method, ultrasonic meters and the wedge incision method.

Sclerometer TQC Sheen TI SP 0010

Testing the hardness and scratch resistance of paint coatings, plastics and related products is possible with a sclerometer. The measuring element in our study is a stylus pushed out by a spring that gives the appropriate pressure to the part. The apparatus can be used for both flat and curved surfaces.

Other elements of the AM3D production line

Explore the all stages of the additive manufacturing process

Do you have a custom order?

Does your order require individual consultation with our experts? Contact us for more details